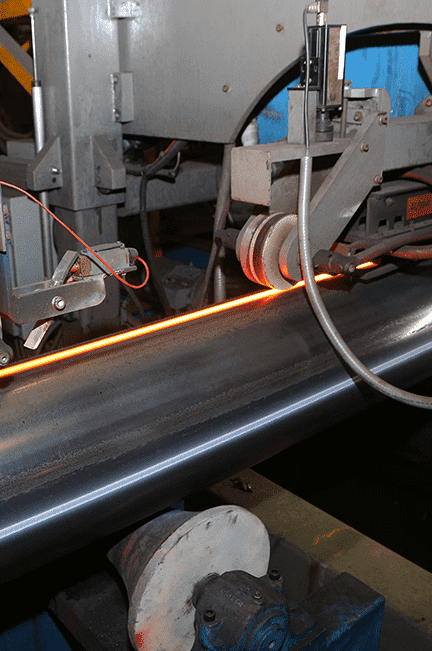

Carbon Steel Line Pipes

Dive deeper to know more about our operational prowess and the range of services we offer through the matrix below.

Welspun Corp is a one-stop service provider of Welded Line Pipes, Ductile Iron Pipes, Stainless Steel Pipes, Tubes and Bars, and is soon starting the production of TMT Bars. We offer end-to-end products, comprehensive pipe solutions and ancillary services, using innovative technology to build our capabilities and focus on future opportunities. We are consistently adding relevant offerings to meet customers’ requirements and cater to the ever-evolving needs of the industry.

Dive deeper to know more about our operational prowess and the range of services we offer through the matrix below.

Upto 18.5 m

2mm - 12.7 mm

1 1/4 inch - 16 inch

Upto API 5L X-80

Upto 18.5 m

6mm - 45 mm

16 inch - 56 inch

Upto 5L X-80

Upto 18 m

5mm - 27 mm

18 inch - 143 inch

Upto API 5L X-80

4 inch - 60 inch

0-180°

(Arc + Tangent) - upto 16m

45mm

25.2 Mn sq.m

2 inch - 140 inch

4.5 inch - 140 inch

Upto 18.5 m

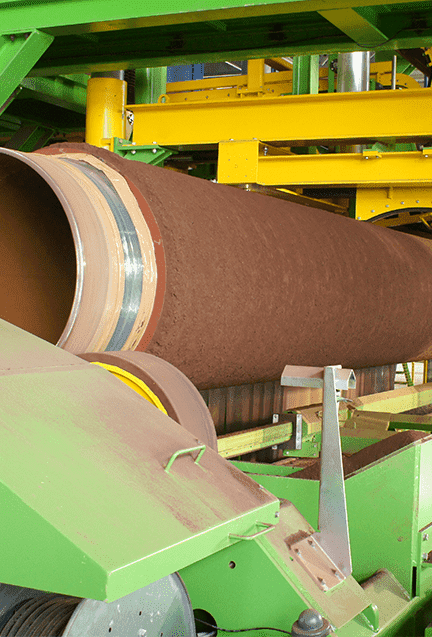

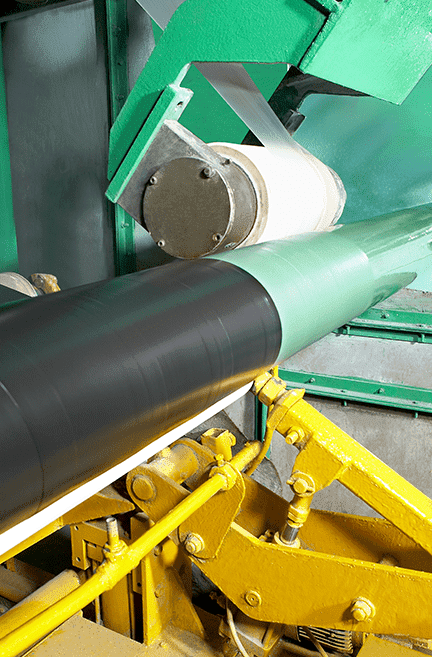

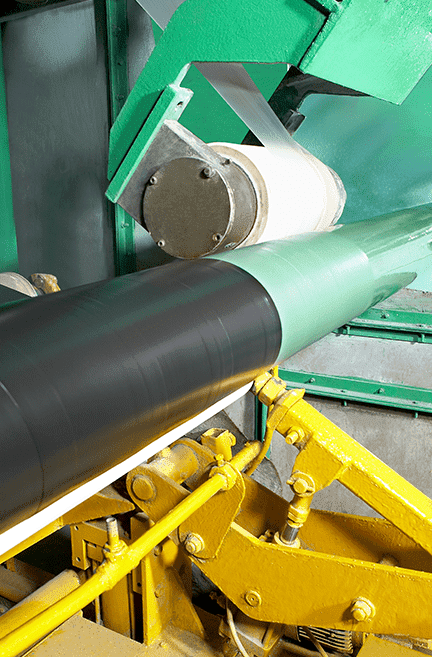

"Type of Coating - 3 Layer Polyethylene / 3 Layer Polypropylene / Single Layer & Dual Layer Fusion Bonded Epoxy(FBE/DFBE), Liquid Epoxy - Flow Coating"

Upto 18.5 m

15 MT Max

40 MT Max

Upto 18 m

6mm - 25.4 mm

18 inch - 100 inch

Upto API 5L X-80

4.5 Mn sq.m

2 inch - 120 inch

Upto 26 m

Type of Coating - 3 Layer Polyethylene / 3 Layer Polypropylene / Single & Dual Layer Fusion Bonded Epoxy (FBE/DFBE) – ARO and Rough coating)

16 inches - 60 inches

Up to 2 inches

Up to 26.2 Meters

Upto 24 m

4mm - 12.7 mm

6 5/8 inch - 20 inch

Upto API 5L X-80 and J55

Upto 24.3 m

8mm - 25.4 mm

24 inch - 60 inch

Upto API 5L X-80

9.1 Mn sq.m

4 inch - 60 inch

24 inch - 60 inch

Upto 24.5 m

Type of Coating - Single & Dual layer Fusion Bonded Epoxy (FBE/DFBE), Liquid Epoxy - Flow Coating.

Sintex Water Tanks are considered as the mark of excellence and innovation in the world of water storage solutions. With over five decades of experience, Sintex holds the distinguished reputation of introducing continuous innovation to the water storage industry. Our water tanks offer a comprehensive selection that cater to the diverse needs of every household. They set a benchmark for quality and reliability in India and are renowned as the healthiest tanks in the country.

Crafted with precision and engineered to perfection, these tanks are designed to safeguard your water supply while ensuring optimal hygiene standards. The wide range of offerings from Sintex offer something for every need; including a technologically advanced Pure Tank that guarantees the purity of stored water and the innovative TruePUF Tank, combining strength and insulation for exceptional performance

Our commitment to delivering the highest quality products is evident in our use of the finest materials and state-of-the-art manufacturing processes. Not only do our tanks boast of an aesthetic appeal, but they are also intelligently engineered to withstand the test of time. Trust Sintex to provide innovative solutions that ensure the safe and efficient storage of your water supply.

Know More

Transform your home into an aesthetic haven with uPVC interiors by Sintex. Along with elevating the appeal of your home, our product portfolio also offers a plethora of practical benefits. Crafted with uncompromising quality, our hassle-free uPVC interiors are remarkably easy to maintain. With longevity as their hallmark, they stand the test of time, proving to be a wise and cost-effective investment.

Embracing the essence of a smart home, Sintex Interior Products provide an exceptional range of options for every corner of your abode. Discover the perfect match for your kitchen cabinets, wall panels, storage units, ceilings, and doors within our extensive collection.

Embodying innovation and creativity, each product reflects our five decades of industry experience, coupled with a relentless pursuit of excellence. Constructed from uPVC, a material renowned for its strength, durability, and lightweight nature, our interiors effortlessly mimic natural elements and are available in a spectrum of captivating colors.

Elevate your living spaces with Sintex uPVC Interiors and experience the pinnacle of style and functionality, all backed by our unwavering commitment to quality and craftsmanship.

Know More

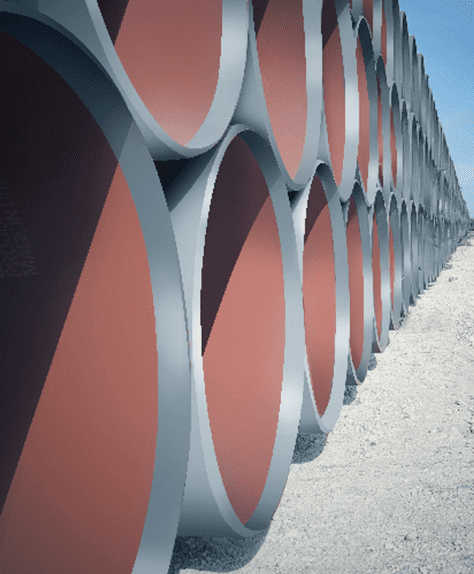

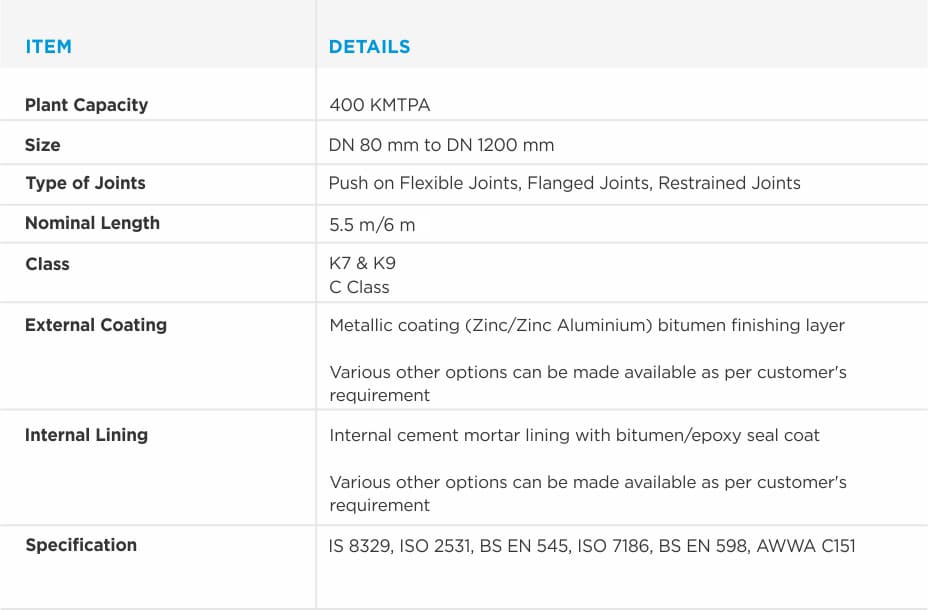

Welspun Corp has set up an integrated Ductile Iron (DI) Pipes facility with a capacity of 400,000 MT along with other value-added ancillary services at Anjar, Gujarat. The DI Pipes produced at this state-of-the-art Greenfield manufacturing unit caters to water infrastructure needs, both in India and globally.

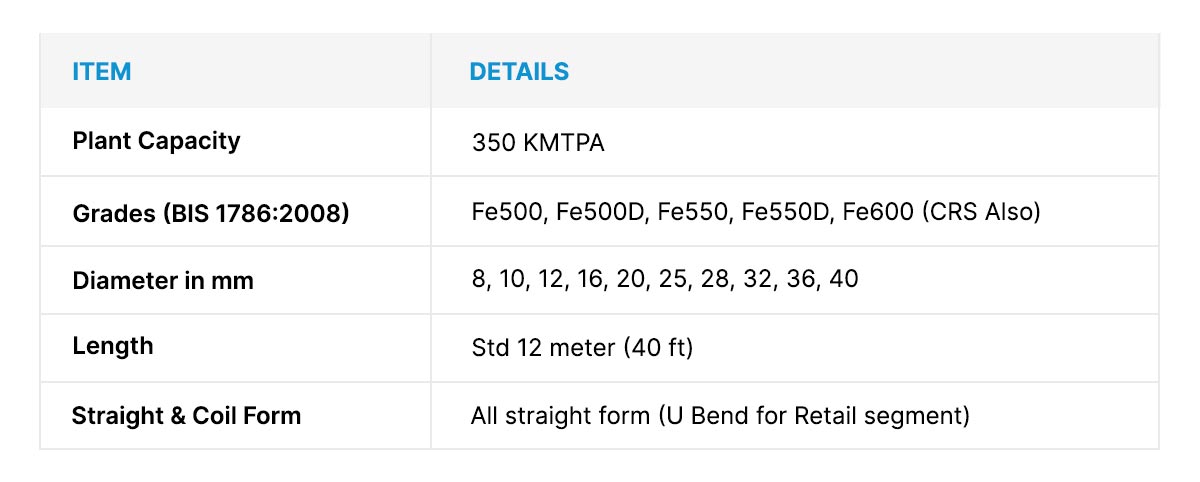

With a keen focus on infrastructure, we are also in the process of augmenting our steel-making facilities by installing a reinforcement steel (TMT rebars) mill that boasts cutting-edge technology, located at Welspun City, in Anjar, Gujarat.

WCL has an existing manufacturing set-up of BIS Certified Steel Billets which will be used as inputs for manufacturing TMT Rebars ranging from 8mm to 32mm, with a total capacity of 350 KMTPA. It aims to emerge as one of the most credible players in the Western and Central parts of India offering high-quality Thermo Mechanically Treated rebars.

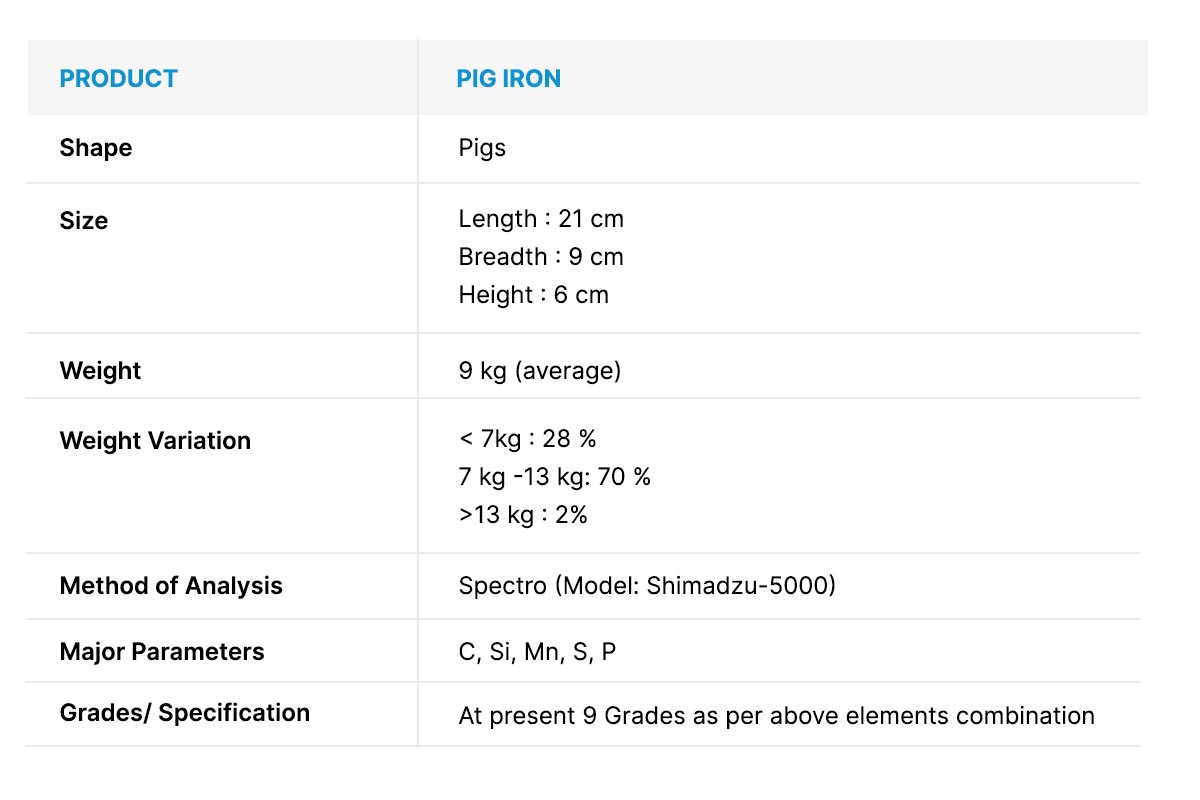

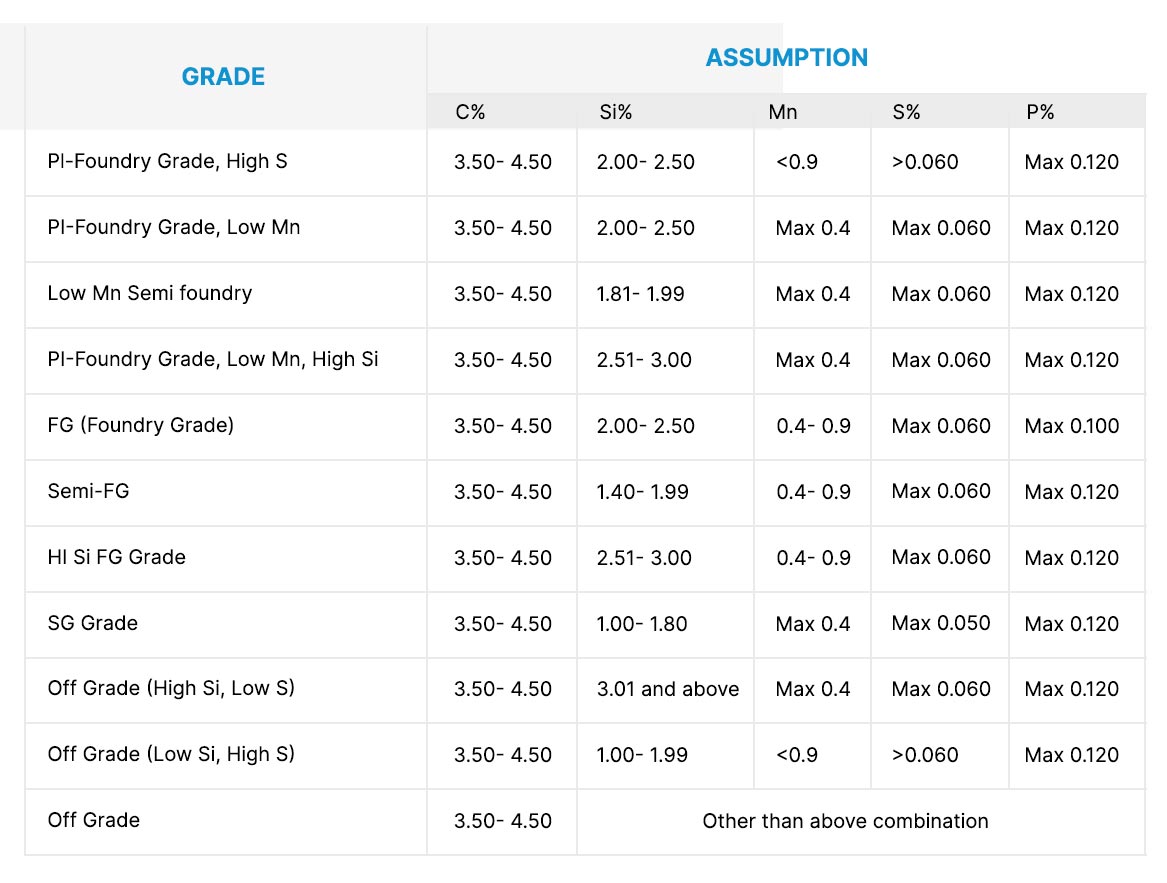

Pig iron, also known as crude iron, is an intermediate product of the iron industry in the production of steel which is obtained by smelting iron ore in a blast furnace. It contains at least 92% Fe and has a very high carbon content, typically 3.5 - 4.5%.

A majority of pig iron is produced and consumed within integrated steel mill complexes, where blast furnace iron is transferred directly to the steel plant in molten liquid form, also known as "hot metal" or "blast furnace iron."